Dr.-Ing. Axel Sielaff

Boiling and Evaporation

Contact

sielaff@ttd.tu-...

work +49 6151 16-22272

fax +49 6151 16-22262

Work

L2|06 211

Peter-Grünberg-Str. 10

64287

Darmstadt

In the boiling and evaporation group, we focus on the two-phase heat transfer of liquids to gases or vapors. Please find more information on our projects below.

Multiscale experiments of boiling of complex fluids on complex surfaces

The project multi-scale experiments on boiling complex liquids on complex surfaces focuses on the analysis of the interactions between heat transfer and evaporation at pilot plant scale. Investigations are carried out with different heaters and fluids, whereby the length scale to be resolved is in the mm range.

Since many boiling phenomena occur on small length scales and influence the entire process, additional investigations are carried out with single bubbles.

Understanding and optimizing evaporation processes for µ-g applications

In addition to the different length scales, the time scales are also a decisive factor in the boiling process. When refrigerants are used, for example, more than 100 bubbles per second can rise at a single cavity.

Under conditions of reduced gravity buoyancy decreases. The bubbles grow more slowly, grow bigger and detach later. In the project “Understanding and optimizing evaporation processes for µ-g applications” we use parabolic flights and cooperate with an international research team within the RUBI experiment. This experiment is to be carried out on the International Space Station in 2019.

Forced Wetting and Dewetting of Complex Surfaces

Some of the occurring interactions are in the sub-millimeter to sub-micrometer range. The formation of a thin film with a thickness of a few micrometers between the bubble and the heated wall should be particularly mentioned. In the project Forced Wetting and Dewetting of Complex Surfaces we can precisely reproduce, investigate and describe this thin film formation.

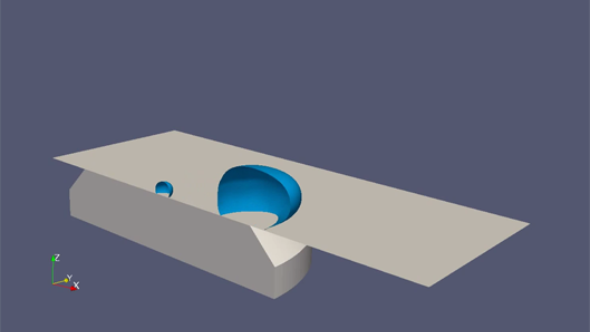

Simulation of bubble boiling

Despite high-resolution measurement technology the smallest length scales are experimentally inaccessible, nor can all parameters be varied independently. Within the project Simulation of bubble boiling we use numerical tools and develop codes to describe the boiling process in detail. Cavities in the heater as well as shear flows are taken into account.

Deposit formation of fuel and AdBlue

In order to transfer our experimental knowledge and experience to current technical processes, we are also investigating the evaporation and deposit formation of fuels and urea-water solutions in the project Deposit formation of fuel and AdBlue both on single droplets and on thin liquid films. The film will be sheared within an air stream on a heated surface. Here we can experimentally map internal motor conditions of 25 – 250°C wall temperature at flow velocities up to 20 m/s.