Yiota Xanthopoulou M.Sc.

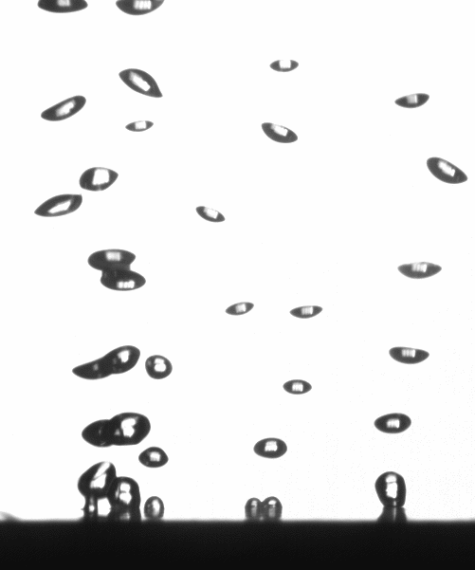

Nucleate boiling

Contact

xanthopoulou@ttd.tu-...

work +49 6151 16-22278

fax +49 6151 16-22262

Work

L2|06 217

Peter-Grünberg-Str. 10

64287

Darmstadt

Links

| Since 2021 | Researcher at the Institute for Technical Thermodynamics, TU Darmstadt |

| 2020–2021 | Master's thesis: “Flow boiling of aqueous surfactant solutions” |

| 2019–2021 | M.Sc. Chemistry, Aristotle University of Thessaloniki |

| 2014–2019 | B.Sc. Chemistry, Aristotle University of Thessaloniki |

Project C02: Multiscale Investigations of Boiling of Complex Fluids on Complex Surfaces

The combination of phase change processes, like boiling and condensation, has been proved to be one of the most effective methods for cooling systems in industry and other applications. One application with great future interest is the cooling of microelectronics, where there is a need for high heat transfer while maintaining a safe system operation. During boiling several boiling regimes can be differentiated. Nucleate boiling is the most desirable regime. It combines high heat fluxes with moderate wall superheats.

The heat transfer mechanism in the case of boiling depends on the liquid’s latent heat of vaporization, on the surface tension, on the surface’s wettability, on the fluid properties for every phase, and the surface’s morphology, roughness, and inclination. Therefore, it is obvious that changes in the mentioned parameters can lead to an optimum heat transfer efficiency, with increased heat transfer coefficient and critical heat flux.

This project aims to investigate the influence of different fluid properties, increasing the complexity of the test fluids, in combination with increasing surface complexity on nucleate boiling heat transfer. Different fluid combinations are used to create mixtures and other complex fluids. To investigate the influence of the mixtures’ and complex fluids’ properties, boiling experiments occur using two different heaters. One of them is made of copper, which is heated via a ceramic heater. This heater is used to study multiple bubbles and very high heat fluxes. The second heater is made of an infrared transparent material sputtered with a metallic layer. This layer is used as a resistance heater. Using a high-speed infrared camera, the local heat flux on the back of the metallic layer can be measured. This allows experiments with single or few bubbles at low or medium heat fluxes.

Error on loading data

An error has occured when loading publications data from TUbiblio. Please try again later.

-

{{ year }}

-

; {{ creator.name.family }}, {{ creator.name.given }}{{ publication.title }}.

; {{ editor.name.family }}, {{ editor.name.given }} (eds.); ; {{ creator }} (Corporate Creator) ({{ publication.date.toString().substring(0,4) }}):

In: {{ publication.series }}, {{ publication.volume }}, In: {{ publication.book_title }}, In: {{ publication.publication }}, {{ publication.journal_volume}} ({{ publication.number }}), ppp. {{ publication.pagerange }}, {{ publication.place_of_pub }}, {{ publication.publisher }}, {{ publication.institution }}, {{ publication.event_title }}, {{ publication.event_location }}, {{ publication.event_dates }}, ISSN {{ publication.issn }}, e-ISSN {{ publication.eissn }}, ISBN {{ publication.isbn }}, DOI: {{ publication.doi.toString().replace('http://','').replace('https://','').replace('dx.doi.org/','').replace('doi.org/','').replace('doi.org','').replace("DOI: ", "").replace("doi:", "") }}, Official URL, {{ labels[publication.type]?labels[publication.type]:publication.type }}, {{ labels[publication.pub_sequence] }}, {{ labels[publication.doc_status] }} - […]

-

Number of items in this list: >{{ publicationsList.length }}

Only the {{publicationsList.length}} latest publications are displayed here.