Wetting of soluble surfaces is present in many branches of industry. Examples can be found in the printing-, cleaning- and the foodindustry. However, the physical phenomena concerning those processes remain unclear. Since the 19th century, scientists around the world have worked on general physical models to describe wetting processes. So far, no generalized forms desribing arbitrary material matching could be deduced. This project aims at improving the knowledge of wetting phenomena regarding solvents on soluble surfaces.

For a broad analysis of wetting phenomena on soluble surfaces, diverse polymer substrates are brought into contact with multiple solvents. Substrates are varied in respect to molar mass, tacticity and mechanical preloads. The usage of multiple solvents enables an evaluation of the effect of solubility on experimental outcomes.

Observations are made on multiple time scales. The spreading of a solvent on a polymer surface just after contact is investigated on the sub micro second scale. On the other hand, surfaces restructuring is observed after droplet spreading an evaporation.

Publications:

- Wolf, Christian; Gambaryan-Roisman, Tatiana (2022): Wetting and evaporation of solvents on thin soluble substrates. In: Colloids and Interfaces, 4 (4), MDPI, e-ISSN 2504-5377, https://doi.org/10.3390/colloids4040048

- Sielaff, Axel; Zimmermann, Matthias; Schweikert, Kai; Hänichen, Philipp; Wolf, Christian; Nejati, Iman; Krempel, Julian; Stephan, Peter (2019): Single bubble pool boiling within micro gravity conditions. 14th International Conference on "Two-Phase Systems for Space and Ground Applications”, Granada, Spain, September 24-27, 2019, https://www.elgra2019.com/

Meeting hygienic standards is essential for the food industry and many others to supply the consumer with safe product. Therefor automatic cleaning in place systems are spread widely within these industries, to maintain product quality. Inevitably, the cleaning process adds extra costs to production such as direct costs (e. g. cleaning liquid) and the loss of production time. In respect to the climate targets of the German Federal Republic, also consumption of resources in cleaning processes should be reduced. For prior reasons the optimization of cleaning processes lays in focus of the following research.

The research project “Discontinuous Cleaning 2” of the IVLV provides process know-how for machine vendors in the food processing industry. In the focus: The potential of pulsation and intermitting flows in increasing efficiency in jet cleaning of large and medium scale containers. The research project was carried out in cooperation between TU Darmstadt and TU Dresden. After the project finish in May 2018, research in this field is continued. Due to the long list of factors of influence, the jet is investigated from the point it is ejected from the nozzle throughout the disintegration during its travel towards the impingement plate. There the wall flow as well as related transfer mechanisms such as cleaning and heat transfer are characterized.

Publications:

- Wassenberg, Joern R. ; Stephan, Peter ; Gambaryan-Roisman, Tatiana (2020): Heat transfer during pulsating liquid jet impingement onto a vertical wall. Heat and Mass Transfer, 2020, Springer, ISSN 09477411, e-ISSN 14321181, https://doi.org/10.1007/s00231-020-02973-z

- Wassenberg, Joern R. ; Stephan, Peter ; Gambaryan-Roisman, Tatiana (2019): The influence of splattering on the development of the wall film after horizontal jet impingement onto a vertical wall. Experiments in Fluids, 60 (11), S. 173. Springer, ISSN 0723-4864, e-ISSN 1432-1114, https://doi.org/10.1007/s00348-019-2810-6

Wetting of a solid by a liquid is an ever existing phenomenon. From a dew drop to ink jet printing we observe wetting of different kind of surfaces with different topographical and mechanical features. Over the past decades, a significant amount of work has been done in order to understand the influence of the mechanical properties of the surface on some of the very well- known wetting-dewetting phenomena such as: Spreading, evaporation and condensation.

Many industrial applications revolve around using an external force to wet or to dewet surfaces. In application we encounter liquids which are not only Newtonian in nature but also non-Newtonian. Because of its relative importance in industry, the influence of the non-Newtonian properties of the liquid on wetting kinetics has also captivated researchers.

Within the scope of this doctoral study, we investigate the influence of the surface deformability on the spreading and drop impact phenomena of non-Newtonian liquids. Experiments are conducted with custom built setups facilitating detailed investigation. Existing models are then compared with the results. Influence of the external body forces on the deformation of Newtonian and non-Newtonian drops are also studied.

Publications:

- Alam, Md Ehsanul (2021): Experimental investigation on the dynamic wetting of deformable substrates: Influence of the rheology of substrate and wetting liquid and external body force. Dissertation, Technische Universität Darmstadt, https://doi.org/10.26083/tuprints-00018499

- Kittel, Hannah M.; Alam, Ehsanul; Roisman, Ilia V.; Tropea, Cameron; Gambaryan-Roisman, Tatiana (2018): Splashing of a Newtonian drop impacted onto a solid substrate coated by a thin soft layer. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 553, S. 89-96, ISSN 0927-7757, https://doi.org/10.1016/j.colsurfa.2018.04.060

- Alam, Ehsanul; Yadav, S.; Schneider, J.; Gambaryan-Roisman, Tatiana (2017): Imbibition of water into substrates prepared by thermal treatment of polydimethylsiloxane layers. Colloids and Surfaces A – Physicochemical and Engineering Aspects, 521, S. 69-77, ISSN 0927-7757, https://doi.org/10.1016/j.colsurfa.2016.09.017

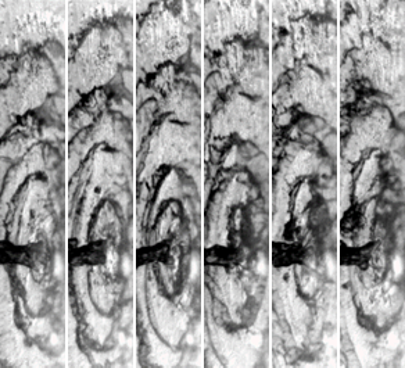

Zero-gravity distillation is a micro distillation process. The working principle is comparable with heat pipes with binary mixtures which are used for cooling purposes. The different boiling points of the fluid components result in a separation of the mixture. The liquid flow is driven by capillary forces. Thus, the process works without gravity and zero-gravity distillation apparatuses can also be used in space. In order to reach a better understanding of zero-gravity distillation, a test rig was built at TTD to investigate the hydrodynamics and heat and mass transfer inside a zero-gravity distillation apparatus. For different fluid mixtures and operating parameters different temperature distributions and curvature distributions of the liquid-vapour interface are established. These distributions depend on the fluid composition at different places in the device and thereby allow a conclusion about the separation efficiency of the process.

The figure shows a micro structured evaporator made of copper. The darker areas in the picture are the area wetted by liquid whereas the brighter areas are not wetted with liquid. In this case, a dry out of the evaporator can be observed since the capillary forces are not sufficient to sustain the liquid flow from the condenser to the evaporator.

Publications:

- Preußer, Niklas (2020): Coupled transport processes in zero-gravity distillation columns. Dissertation, Technische Universität Darmstadt, https://doi.org/10.25534/tuprints-00011447

- Rieks, Sebastian; Wende, Marc; Preußer, Niklas; Gambaryan-Roisman, Tatiana; Kenig, Eugeny Y. (2019): A hydrodynamic analogy based modelling approach for zero-gravity distillation with metal foams. Chemical Engineering Research and Design, 147, S. 615-623, Elsevier, ISSN 2638762, https://doi.org/10.1016/j.cherd.2019.05.022

- Preußer, Niklas; Rieks, Sebastian; Kenig, Eugeny Y.; Stephan, Peter; Gambaryan-Roisman, Tatiana (2018): Transport processes and separation in zero-gravity destillation. IHTC 16 – International Heat Transfer Conference 16 Digital Libary, August 10-15, Beijing, China, Connecticut, Begellhouse, Connecticut, ISSN 2377-424X, https://doi.org/10.1615/IHTC16.her.023300

- Rieks, Sebastian; Preußer, Niklas; Gambaryan-Roisman, Tatiana; Kenig, Eugeny Y. (2018): Zero-gravity distillation with metal foams: A modelling approach. CHEMICAL ENGINEERING TRANSACTIONS, 69, S. 283 – 288, ISSN 2283-9216, https://doi.org/10.3303/CET1869048

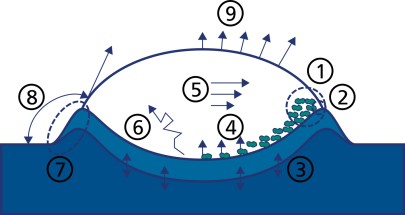

Falling films are used in many technical processes for cooling, condensation and evaporation. The hydrodynamics and the heat transfer of these wavy liquid films are important for the design of machines. The literature describes the hydrodynamics of thin films on vertical walls in detail, revealing that the waves of the film have a positive impact on the heat transfer. However, extensive studies on the impact of the stimulation frequency of the waves and their amplitude on the heat transfer of the film have not yet been sufficiently performed.

Due to this, the present work investigated the influence of wave stimulation on heat transfer. Thus, a solid basis for following work was created for this topic. For this purpose, a test stand was set up with which the flow characteristics and the heat transfer of a defined, periodically stimulated falling film can be investigated in a high-resolution manner. The film thickness was recorded with a chromatic-confocal distance measuring system and the film surface was photographed and evaluated with a camera system. The heat transfer was analyzed with wall temperature measurements.

The experiments were carried out in a wide parameter range with the specifically varied parameters frequency and amplitude of stimulation, as well as mass flow, heat flux and angle of inclination of the wall. First, it was shown that the wave forms develop depending on the stimulation frequency along the flow direction. The amplitude of the periodic stimulation, which was not analyzed in previous work, has a significant impact on the development of the waves. The other investigated wave characteristics include the average film thickness, the wave frequency, the wave maxima and minima, the film thickness distribution, the wavelength and velocity.

A comparison of the experimental results with extrapolated correlations did not provide a sufficient agreement and the parameters of the correlations were adapted to the experimental data. The analysis of the wall temperature measurements also revealed a strong frequency-dependent influence of the wave stimulation on the heat transfer. In certain frequency ranges, the heat transfer could be improved. These frequency ranges correspond to the occurrence of pronounced wave minima in the film flow.

Publications:

- Schröder, Timm (2019): Strömungscharakteristika und Wärmeübertragung eines angeregten Fallfilms. Dissertation, Technische Universität Darmstadt, https://tuprints.ulb.tu-darmstadt.de/id/eprint/8742

Complex liquids such as nanoparticle dispersions, vesicle dispersions and microemulsions find widespread use in several homecare, personal care and pharmaceutical formulations. The main objective of my research is to develop a better understanding of the interaction of such complex liquids with real-life porous substrates such as textiles, hair and paper in order to improve the performance of applications such as fabric softening, hair conditioning and inkjet printing. The interaction of the complex liquid with porous substrates may involve diverse phenomena, such as, (i) deposition of the actives (nanoparticles/vesicles/oil droplets) on the substrate surfaces as in the case of fabric softening and hair conditioning , (ii) spreading and imbibition of complex liquid droplets on porous cellulose filter papers as in the case of inkjet printing, and (iii) evaporation of complex liquid droplets after imbibition on the porous substrate leaving the dispersed actives behind.

Our work has provided several new insights into such interactions, for example, in the case of fabric softening, it has been explained what factors determine whether the softening actives deposit on the external fabric surfaces or they penetrate into the fabric. The location of deposited actives is an extremely important parameter governing its performance. Furthermore, ongoing investigations on the wetting of complex liquid droplets on porous substrates and the subsequent evaporation revealed that deposition in the form of a ring like in the coffee-ring effect. The mechanism of the coffee ring formation on porous substrates is presently being investigated. The learnings from the project are promising and might have implications in several applications.

Publications:

- Kumar, Abhijeet (2020): Wetting, evaporation and deposition processes in interaction of complex liquid formulations with porous substrates. Dissertation, Technische Universität, https://doi.org/10.25534/tuprints-00014211

- Kumar, Abhijeet; Kleinen, Jochen; Venzmer, Joachim; Trybała, Anna; Starov, Victor; Gambaryan-Roisman, Tatiana (2019): Spreading and imbibition of vesicle dispersion droplets on porous substrates. Colloids and Interfaces, 3 (3), S. 53, ISSN 2504-5377, https://doi.org/10.3390/colloids3030053

- Kumar, Abhijeet; Trambitas, Alexandra; Peggau, Jörg; Dahl, Verena; Venzmer, Joachim; Gambaryan-Roisman, Tatiana; Kleinen, Jochen (2019): Charge and size matters — How to formulate organomodified silicones for textile applications. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 560, S. 180 – 188, ISSN 0927-7757, https://doi.org10.1016/j.colsurfa.2018.09.080

- Kumar, Abhijeet; Kleinen, Jochen; Gambaryan-Roisman, Tatiana; Venzmer, Joachim (2018): Electrokinetic investigation of deposition of cationic fabric softener vesicles on anionic porous cotton fabrics. Journal of Colloid and Interface Science, 514, S. 132-145, ISSN 0021-9797, https://doi.org/10.1016/j.jcis.2017.11.062

Currently, the design of single machines and production steps within an overall production process is mostly carried out separately. In this project all components are considered as a cross-linked system. This includes also the factory building which has to be heated or cooled. This is done exemplarily for the reference process of the ETA-factory. Besides developing a method for modeling a production process the following questions are to be answered:

- Which increase in efficiency can be achieved via cross-linking?

- Which measures are economic?

- Which characteristic numbers are suitable to evaluate a production process?

Publications:

Winterling, Jella ; Dammel, Frank ; Stephan, Peter (2017): Exergy analysis of thermally interconnected manufacturing processes. Proceedings of the 9th International Exergy, Energy and Environment Symposium, May 14-17, Split, Croatia